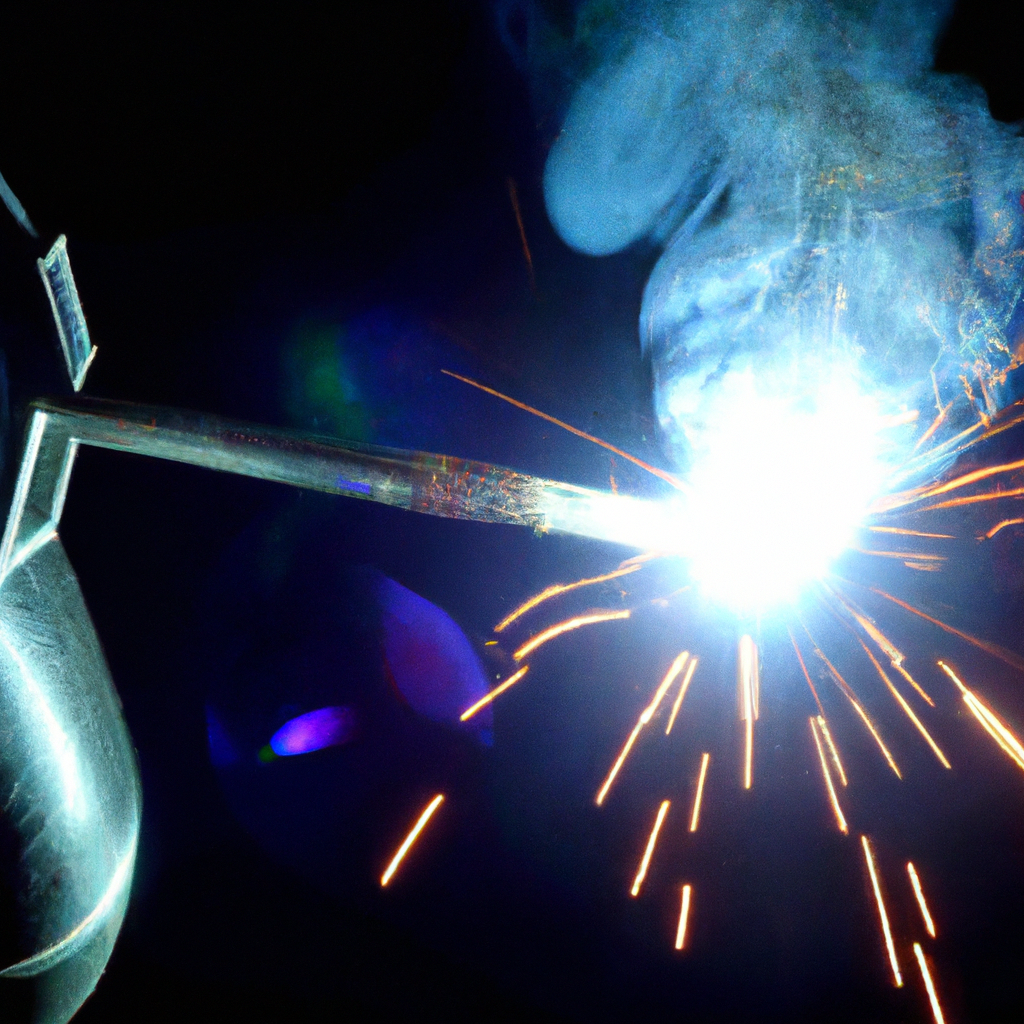

Are you considering getting into welding but unsure which type to learn? Stick welding and MIG welding are two popular options, each with their own advantages and disadvantages. Stick welding, also known as shielded metal arc welding (SMAW), is versatile and can be used in various environments, including outdoors. On the other hand, MIG welding, or metal inert gas welding, is easier to learn and offers quicker, cleaner welds. Ultimately, the decision of whether to learn stick or MIG welding depends on your specific needs and preferences. Let’s take a closer look at the pros and cons of each to help you make an informed choice.

Understanding Stick Welding

Definition of Stick Welding

Stick welding, also known as shielded metal arc welding (SMAW), is a welding process that uses a consumable electrode coated in flux to join metals. It is one of the most widely used welding techniques and is highly versatile, making it suitable for a wide range of applications.

History of Stick Welding

Stick welding has a rich history that dates back to the 19th century. It was initially developed as a means to repair railroad tracks and has since evolved into a widely used welding technique. Over the years, advancements in technology have improved the efficiency and effectiveness of stick welding, making it a popular choice among welders.

The process: How Does Stick Welding Work?

Stick welding involves creating an electric arc between the coated electrode and the metal being welded. This arc generates intense heat, which melts both the electrode and the metal, creating a molten pool. As the weld cools, it solidifies and fuses the two pieces of metal together, creating a strong and durable bond.

Common Uses of Stick Welding

Stick welding is often used in construction, fabrication, and repair work. It is particularly well-suited for welding heavy materials, such as steel and cast iron. Stick welding is commonly used in the construction of steel structures, bridges, pipelines, and pressure vessels. It is also frequently used for maintenance and repair work, such as fixing farm equipment or welding structural components.

Pros of Stick Welding

Versatility of Stick Welding

One of the major advantages of stick welding is its versatility. it can be used to weld a wide variety of metals, including steel, cast iron, stainless steel, and aluminum. This makes it a valuable skill for welders working on diverse projects.

Suitability for Outdoor Welding

Stick welding is particularly well-suited for outdoor welding because it does not require a shielding gas. The flux coating on the electrode provides a protective shield that prevents atmospheric contamination, making it ideal for welding in windy or adverse weather conditions.

Ability to Handle Dirty or Rusty Materials

Stick welding excels at welding dirty or rusty materials. The electrode’s flux coating acts as a cleaning agent, removing dirt, rust, and other impurities, ensuring a strong weld. This makes stick welding a preferred method for repairs and maintenance jobs where the condition of the metal may be compromised.

Cost-effectiveness of Equipment and Materials

Stick welding is a cost-effective option for many welders. The equipment and consumables used in stick welding, such as electrodes and power sources, tend to be more affordable compared to other welding processes. This makes it an attractive choice for welders on a budget or for those starting their welding journey.

Cons of Stick Welding

Difficulty Level of Stick Welding

Stick welding can be more challenging to master compared to other welding processes. It requires precise control of the arc length and movement speed to ensure a quality weld. Additionally, the technique of striking an arc can be challenging for beginners, requiring practice and skill development.

Poor Weld Appearance

Stick welding can sometimes result in a rougher weld appearance compared to other welding techniques. The flux coating can leave behind a residue that needs to be removed through thorough cleaning and grinding. However, with proper technique and practice, welders can achieve aesthetically pleasing results.

Safety Risks Associated with Stick Welding

Stick welding involves working with high temperatures and intense light emissions. This exposes welders to various safety risks, such as eye damage from arc radiation, fumes, and electric shocks. Proper safety measures, such as wearing a welding helmet, gloves, and protective clothing, are crucial to minimize these risks.

Time-consuming Cleaning Process

Stick welding requires careful cleaning and preparation of the weld area before and after welding. This includes removing rust, paint, and other contaminants. The post-weld cleaning process can be time-consuming, adding to the overall welding time.

Understanding MIG Welding

Definition of MIG Welding

MIG welding, short for metal inert gas welding, is a widely used welding process that utilizes a continuously fed wire electrode and a shielding gas to join metals. It is known for its speed, ease of use, and versatility.

History of MIG Welding

MIG welding was developed in the 1940s as a faster alternative to stick welding. Its popularity grew rapidly due to its efficiency and ability to produce high-quality welds. Since its inception, MIG welding has become a preferred method in various industries, including automotive, manufacturing, and construction.

The process: How Does MIG Welding Work?

MIG welding involves feeding a continuous wire electrode, typically made of steel or aluminum, through a welding gun. The electrode is consumed during the welding process, providing the filler material to create the weld. A shielding gas, such as argon or a mixture of gases, is also used to protect the weld from atmospheric contamination.

Common Uses of MIG Welding

MIG welding is commonly used in the automotive industry for body repairs and manufacturing processes. It is also widely employed in fabrication shops, where it is used to weld mild steel, stainless steel, and aluminum. Other applications include manufacturing of furniture, appliances, and HVAC systems.

Pros of MIG Welding

Ease of Learning and Use

MIG welding is considered one of the easiest welding processes to learn and use. The continuous wire feeding mechanism reduces the need for constant electrode changes, making it a more efficient process. This makes MIG welding an excellent choice for beginners or those seeking a fast and straightforward welding technique.

High Welding Speed

MIG welding is known for its high welding speed. The continuous wire feed allows for rapid deposition of filler material, resulting in faster welds compared to stick welding. This makes MIG welding highly productive, especially in industrial applications where time is of the essence.

Possibility to Weld Variety of Metals

MIG welding is versatile and can be used to weld a wide range of metals, including carbon steel, stainless steel, aluminum, and even some exotic alloys. This versatility makes it a preferred choice for welders working on projects that require welding different types of metals.

Cleaner Welds with Less Spatter

MIG welding typically produces cleaner welds with minimal spatter compared to stick welding. The use of shielding gas helps create a controlled environment that minimizes oxidation and atmospheric contamination. This results in cleaner, more aesthetically pleasing welds that require less post-weld cleaning.

Cons of MIG Welding

High Costs of Equipment

One of the drawbacks of MIG welding is the higher initial cost of equipment. MIG welding machines, wire feeders, and shielding gas cylinders can be more expensive compared to stick welding equipment. However, the long-term benefits of increased productivity and cleaner welds can outweigh the higher upfront investment.

Difficulty in Working Outdoors

MIG welding requires a clean and controlled environment, which can be challenging to achieve outdoors. Factors such as wind, moisture, and temperature fluctuations can affect the quality of the weld. Welding outdoors with MIG welding may require additional precautions and setup to ensure optimal welding conditions.

Inadvisability for Thicker Materials

MIG welding is generally not recommended for welding thicker materials. It is better suited for thinner materials, typically ranging from 0.6mm to 6mm. Thicker materials may require multiple passes or a different welding process, such as stick welding or flux-cored arc welding, to achieve satisfactory results.

Necessity for Clean Work Surface

MIG welding requires a clean work surface to achieve high-quality welds. Any contaminants, such as rust, paint, or dirt, can negatively impact the weld’s integrity. Thorough cleaning and preparation of the work surface are essential to ensure proper fusion and a strong bond.

Comparison of Stick and MIG Welding

Speed and Efficiency

In terms of speed and efficiency, MIG welding generally outperforms stick welding. The continuous wire feed and faster deposition rates of MIG welding contribute to quicker welding times, especially for longer or repetitive welds. Stick welding, on the other hand, requires frequent electrode changes and can be slower overall.

Precision and Cleanliness

When it comes to precision and cleanliness of welds, MIG welding offers more control and produces cleaner results. The use of shielding gas minimizes spatter and oxidation, resulting in aesthetically pleasing welds that require less post-weld cleanup. Stick welding may require additional grinding and cleaning due to flux residue and can yield rougher weld appearances.

Versatility

Both stick welding and MIG welding are versatile processes, but they excel in different applications. Stick welding is well-suited for heavier materials, such as thick steel or cast iron, making it a preferred choice for construction and repair work. MIG welding, on the other hand, is more suitable for thinner materials and is widely used in automotive, manufacturing, and fabrication industries.

Money and Time Factor

Stick welding is generally more cost-effective in terms of equipment and consumable costs. Stick welding machines and electrodes are typically more affordable than MIG welding equipment. Additionally, stick welding requires less setup time, as it does not require gas cylinders or wire feeders. However, MIG welding can offer long-term cost savings with its higher productivity and cleaner welds.

Learning Curve

Stick welding has a steeper learning curve compared to MIG welding. The control of arc length, electrode angle, and speed requires practice and skill development. MIG welding, on the other hand, is easier to learn and offers a more straightforward technique. Beginners may find MIG welding more accessible, but both techniques require continuous learning and practice to achieve proficiency.

Choosing Between Stick and MIG Welding Based on Specific Needs

Determining the Material to be Welded

Consider the material you will primarily be welding when choosing between stick and MIG welding. If you will be working with heavier materials, such as thick steel or cast iron, stick welding may be the better choice. For thinner materials like sheet metal or aluminum, MIG welding would be more suitable.

Determining the Work Environment

Evaluate your work environment when deciding between stick and MIG welding. If you will be working predominantly outdoors or in adverse conditions, stick welding’s ability to handle wind and atmospheric contamination without the need for shielding gas may be advantageous. On the other hand, if you will be primarily working in a controlled indoor environment, MIG welding’s cleanliness and precision may be more appealing.

Considering Cost and Time Factors

Consider your budget and project timelines when choosing between stick and MIG welding. Stick welding generally has lower equipment and consumable costs, making it a more affordable option. Additionally, stick welding requires less setup time, which can be beneficial for projects with tight deadlines. However, if productivity, cleaner welds, and long-term cost savings are crucial, MIG welding may be a better investment despite the higher upfront costs.

Assessing Personal Skills and Experience

Assess your personal skills and experience level when deciding between stick and MIG welding. Stick welding requires more practice and skill development due to its technical aspects, such as striking the arc and controlling the electrode. If you are a beginner or have limited welding experience, MIG welding may be a more accessible option. However, if you enjoy the challenge and are willing to invest time in learning stick welding, it can be a rewarding skill to master.

The Importance of Safety in Both Methods

Welding Safety Gear

In both stick and MIG welding, wearing appropriate safety gear is crucial to protect against potential hazards. This includes a welding helmet with a proper shade level, safety glasses, flame-resistant clothing, welding gloves, and steel-toed boots. Safety gear should be of high quality and well-maintained to ensure maximum protection.

Potential Hazards and How to Minimize Them

Stick and MIG welding pose various hazards, including exposure to arc radiation, fumes, and electric shocks. To minimize these risks, ensure proper ventilation in the work area to reduce fume exposure. Positioning yourself to minimize direct exposure to the welding arc and using welding screens or curtains can protect against arc radiation. Following correct electrical grounding procedures and using insulated tools help mitigate the risk of electric shocks.

Workplace Safety Standards

Adhering to workplace safety standards is essential in both stick and MIG welding. Familiarize yourself with safety guidelines and regulations applicable to your location. Ensure your work area is well-maintained, organized, and free from clutter to minimize tripping hazards. Regularly inspect your equipment, checking for any defects or damage that may compromise safety. Establishing a safety-conscious work environment and promoting safe practices among fellow workers is paramount in both stick and MIG welding.

Training Opportunities and Resources for Welding

Professional Courses and Certifications

Consider enrolling in professional welding courses and certifications to enhance your skills and knowledge in both stick and MIG welding. Many technical schools, community colleges, and vocational institutes offer comprehensive welding programs that cover various welding techniques. These courses often provide hands-on training, safety education, and theoretical knowledge to equip you with the necessary skills for a successful welding career.

Online Learning Resources

Online learning platforms and resources offer convenient options for learning stick and MIG welding. Many websites and YouTube channels provide instructional videos, tutorials, and forums where experienced welders share their knowledge and expertise. These resources can be particularly beneficial for beginners or those looking to sharpen their welding skills through self-paced learning.

Workshop or Community College Courses

Workshops and community college courses provide opportunities for hands-on learning and practice in a structured environment. These short-term courses are usually conducted by experienced instructors who can provide guidance and feedback as you learn stick and MIG welding techniques. Workshops and community college courses also provide networking opportunities with fellow welding enthusiasts.

Apprenticeships and Internships

Consider pursuing an apprenticeship or internship in the welding industry to gain practical, real-world experience. Apprenticeships provide hands-on training under the supervision of experienced welders, allowing you to apply the skills and knowledge learned in training programs. Internships offer valuable opportunities to work alongside professionals, gaining insights into the welding industry and its specific applications.

In conclusion, both stick welding and MIG welding have their advantages and disadvantages. The choice between the two ultimately depends on specific needs, such as the materials being welded, the work environment, budget considerations, and personal skills and experience. Safety should always be a top priority in both welding methods, with proper safety gear, hazard minimization, and adherence to workplace safety standards. Various training opportunities and resources, including professional courses, online learning platforms, workshops, and apprenticeships, can help individuals develop their welding skills in both stick and MIG welding.