Stick welding is a widely used technique in the field of welding, known for its versatility and durability. Whether you are an experienced welder or just starting out, understanding the fundamentals of stick welding welds is crucial. In this article, we will explore the world of stick welding, unraveling the secrets behind creating strong and long-lasting welds through this popular welding method. So, grab your welding helmet and let’s dive into the world of stick welding welds!

Stick Welding Basics

What is Stick Welding?

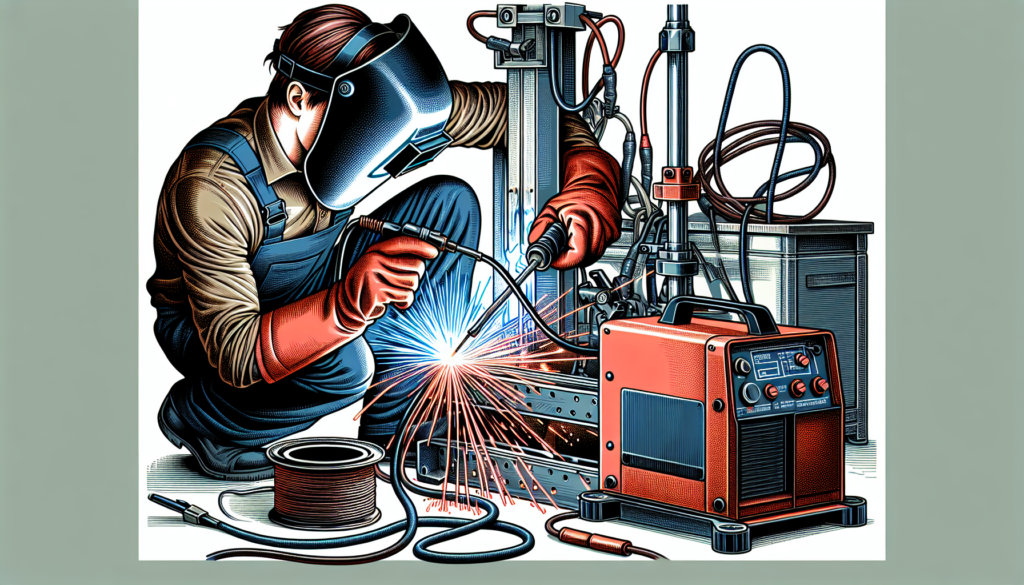

Stick welding, also known as shielded metal arc welding (SMAW), is a welding process that uses a consumable electrode covered in a protective flux coating. This process is widely used in the construction industry and is well-suited for welding thicker materials, such as steel and iron. Stick welding is known for its simplicity and versatility, making it a popular choice for both professional welders and DIY enthusiasts.

Advantages and Disadvantages of Stick Welding

Stick welding offers several advantages. Firstly, it can be performed in outdoor or windy conditions, making it a flexible option for various worksites. Additionally, it is a cost-effective method as it does not require expensive equipment or gas cylinders. Stick welding also allows for welding in multiple positions, including overhead and vertical positions.

However, there are some disadvantages to stick welding. It produces more spatter compared to other methods, which can result in a less aesthetically pleasing weld. This process also requires frequent electrode changes, reducing the welder’s efficiency. Additionally, stick welding may not be suitable for welding thinner materials due to its higher heat input.

Stick Welding Equipment and Tools

To engage in stick welding, you will need the following equipment and tools:

- Welding machine: Stick welding requires a welding machine capable of providing direct current (DC) power. It can be an AC/DC or DC-only machine, depending on your specific welding needs.

- Electrodes: Stick welding electrodes are available in various types, each suitable for different materials and applications. They come in different diameters, and it is essential to choose the right size for your project.

- Welding gloves: A good pair of welding gloves will provide protection from sparks and heat. Look for gloves made from durable materials, such as leather, that offer both heat and electrical resistance.

- Welding helmet: A welding helmet with a tinted lens is crucial to shield your eyes from harmful UV rays and intense light produced during the welding process.

- Welding apron: A welding apron made from flame-resistant materials can provide additional protection for your body against sparks and spatter.

- Chipping hammer and wire brush: These tools are used to remove excess slag and clean the weld surface before starting a new weld.

Preparing for Stick Welding

Safety Precautions

Before starting any welding project, it is essential to prioritize safety. Here are some safety precautions to consider when stick welding:

- Protective clothing: Wear flame-resistant clothing, including a long-sleeved shirt, long pants, and steel-toed boots to protect yourself from sparks and hot materials.

- Eye protection: Always wear a welding helmet with a proper tinted lens to shield your eyes from the intense light and UV radiation generated by the welding process.

- Ventilation: Ensure that you are working in a well-ventilated area or use ventilation fans to remove harmful welding fumes.

- Fire prevention: Keep a fire extinguisher nearby and remove any flammable materials from your work area to prevent accidents.

- Ground your equipment: Properly ground your welding equipment to reduce the risk of electric shocks.

Choosing the Right Electrode

Selecting the correct electrode is crucial for achieving quality welds. The choice of electrode depends on the material being welded, the welding position, and the desired weld characteristics. The American Welding Society (AWS) categorizes electrodes into different types and classifications known as the “AWS electrode identification system.” It is essential to refer to this system and consult electrode manufacturer guidelines to select the appropriate electrode for your specific welding application.

Preparing the Metal Surface

Before starting the welding process, it is crucial to prepare the metal surface to ensure proper weld penetration and adhesion. Follow these steps to prepare the metal surface:

- Clean the surface: Use a wire brush or grinder to remove any dirt, rust, or paint from the metal surface to be welded.

- Bevel the edges: For thicker materials, consider beveling the edges to ensure full penetration. This involves grinding an angled edge to allow the weld to reach the root of the joint more effectively.

- Proper fit-up: Ensure that the pieces to be welded are properly aligned and securely clamped to prevent any movement during the welding process.

Stick Welding Techniques

Starting the Arc

Starting the arc is a crucial step in stick welding. Follow these steps to start the arc:

- Establish a proper stance: Position yourself comfortably with a stable stance and a good line of sight to the weld. Your body should be positioned slightly ahead of the welding hand.

- Strike the electrode: With the electrode holder firmly in your hand, strike the electrode against the metal to create an initial spark and initiate the arc.

- Establish a stable arc: Once the arc is established, maintain a stable arc length and proceed with the welding process.

Maintaining the Arc Length

Maintaining the correct arc length is critical for achieving quality welds. The arc length refers to the distance between the tip of the electrode and the weld joint. Here are some tips for maintaining the right arc length:

- Typically, a gap of around 1/8 inch to 3/16 inch (3-5mm) is maintained between the electrode and the workpiece.

- Too long of an arc length can result in a weak, inconsistent weld, while too short of an arc length can cause excessive spatter and electrode sticking.

- Practice maintaining a consistent arc length by adjusting your hand positioning and controlling the torch movement.

Weaving Techniques

Weaving techniques are commonly used in stick welding to distribute heat evenly and create stronger welds. Two commonly used weaving techniques are:

- Stringer bead: This technique involves moving the electrode in a straight line along the joint, creating a narrow and uniform weld bead. It is typically used for flat and horizontal welding positions.

- Zigzag weave: This technique involves moving the electrode in a zigzag pattern along the weld joint, creating a wider weld bead. It is often used for vertical and overhead welding positions.

Layering and Fillet Welds

For thicker materials or when additional strength is required, layering and fillet welds can be used. Layering involves completing multiple passes or layers of welds, allowing each layer to cool before adding the next. Fillet welds are used to join two pieces of metal at a right angle or in a tee joint configuration, forming a triangle-shaped weld.

Vertical and Overhead Welds

Vertical and overhead welds require additional skill and technique due to the effect of gravity. When performing vertical and overhead welds, consider these tips:

- Adjust the welding amperage to compensate for the additional heat dissipation in vertical and overhead positions.

- Use shorter arc lengths to prevent excessive spatter and improve control.

- Employ weaving techniques to distribute the heat evenly and ensure proper fusion.

Common Stick Welding Defects

Porosity

Porosity refers to the presence of gas pockets or voids within the weld. It can weaken the weld and compromise its integrity. Porosity can result from several factors, such as inadequate shielding gas coverage, contaminated electrodes, or insufficient cleaning of the metal surface. To minimize porosity, ensure proper electrode storage, use clean materials, and maintain sufficient shielding gas coverage.

Undercutting

Undercutting occurs when a groove or depression forms at the weld toe, often leading to a weaker joint. Undercutting may result from excessive heat input, improper welding technique, or excessive travel speed. To prevent undercutting, control the heat input, maintain the correct travel speed, and ensure consistent electrode angles.

Incomplete Fusion

Incomplete fusion refers to the incomplete bonding of the weld metal to the base metal or between multiple weld passes. It can weaken the weld joint, making it susceptible to cracking and failure. Incomplete fusion may occur due to insufficient heat input, improper electrode manipulation, or inadequate cleaning of the joint. To achieve complete fusion, ensure proper heat input, use proper weaving techniques, and maintain a clean weld joint.

Cracks

Cracks in stick welding can be caused by several factors, including excessive heat, rapid cooling, inadequate preheating, or improper joint preparation. These cracks can compromise the strength of the weld and lead to failure. To prevent cracks, control the heat input, use proper preheating techniques, and ensure adequate joint preparation.

Spatter

Spatter refers to the small metal fragments that can be expelled during the welding process and stick to the surrounding areas. It can be unsightly and create additional cleanup work. Spatter is typically caused by excessive heat, improper welding technique, or the use of contaminated electrodes. To minimize spatter, control the heat input, practice proper welding techniques, and use clean electrodes.

Tips for Achieving Quality Stick Welds

Maintaining Proper Electrode Angle

The electrode angle plays a crucial role in the quality of the weld. The angle refers to the positioning of the electrode relative to the welding direction. For most welding applications, a slight drag technique with a 10-15 degree angle is recommended. However, some welds may require different angles. Experiment with different angles to determine the optimal electrode position for your specific project.

Controlling Weld Speed

Welding speed affects the quality and appearance of the weld. Moving too quickly can result in a weak or incomplete weld, while moving too slowly can lead to excessive heat input, causing distortion or burn-through. It is essential to maintain a steady and consistent welding speed that allows for proper fusion and penetration.

Ensuring Sufficient Weld Penetration

Sufficient weld penetration is crucial for creating a strong and reliable weld joint. To ensure proper penetration, use the appropriate amperage and electrode size for the thickness of the metal being welded. Beveling the edges, if necessary, can also improve penetration by allowing better access for the weld.

Managing Heat Input

Controlling the heat input is essential to prevent distortion, warping, and burn-through. Adjust the welding amperage according to the thickness of the material and the desired penetration. Practice proper technique, such as pausing at the edges and using weaving techniques, to distribute heat evenly and avoid concentrated overheating.

Using Proper Welding Techniques

Proper welding techniques, such as maintaining a consistent arc length, using the correct weaving pattern, and controlling the travel speed, are key to achieving quality stick welds. Take the time to practice and hone your skills, as consistent technique will improve weld appearance and strength.

Welding Positions and Applications

Flat Position Welding

Flat position welding refers to welding performed horizontally on a flat surface. It is the easiest welding position and provides good control over the weld puddle. Flat position welding is commonly used in fabrication, construction, and metalworking projects.

Horizontal Position Welding

Horizontal position welding involves welding the joint in a horizontal orientation. It presents some challenges due to the increased risk of weld deformation caused by gravity. Horizontal welding is commonly used in pipeline construction, shipbuilding, and structural steel fabrication.

Vertical Position Welding

Vertical position welding requires welders to maneuver their electrodes up and down while performing the weld. It demands additional skills and technique to prevent excessive slag and achieve proper penetration. Vertical welding is often used in applications such as building columns, beams, and tanks.

Overhead Position Welding

Overhead position welding is considered the most challenging welding position. Welding overhead requires welders to work against gravity, which can lead to difficulties in controlling slag and maintaining proper penetration. Overhead welding is commonly used in applications such as bridge construction, pipeline repairs, and shipbuilding.

Common Applications of Stick Welding

Stick welding is widely used in various industries and applications, including:

- Construction: Stick welding is commonly applied in the construction industry for structural steel fabrication, building maintenance, and infrastructure projects.

- Pipeline welding: Pipelines, both onshore and offshore, often utilize stick welding due to its versatility and ability to weld in different positions.

- Shipbuilding: Stick welding is undertaken during ship construction to join steel plates, build structural components, and create watertight seals.

- Repair and maintenance: Stick welding is suitable for repair and maintenance work, allowing welders to fix broken or damaged metal structures easily.

Stick Welding Troubleshooting

Common Issues and Solutions

Stick welding can sometimes present challenges and issues that need troubleshooting. Here are some common issues and their potential solutions:

- Excessive spatter: Adjust the amperage, electrode angle, or electrode type to reduce spatter. A clean metal surface and proper techniques can also help minimize spatter.

- Poor fusion and penetration: Increase the amperage, adjust the electrode angle, and practice proper weaving techniques to achieve better fusion and penetration.

- Inconsistent weld appearance: Ensure a clean, well-prepared surface, maintain a stable arc length, and practice a consistent welding technique to improve the overall aesthetic of the weld.

Adjusting Amperage and Polarity

The amperage and polarity settings significantly influence the performance and quality of a stick weld. Higher amperage allows for deeper penetration, while lower amperage is suitable for thinner metals. Polarity refers to the direction of current flow. Most stick welding machines offer DC current with reverse polarity (electrode positive). Consult the welding machine specifications and electrode manufacturer guidelines to determine the appropriate settings for your application.

Addressing Arc Blow

Arc blow occurs when the welding arc is deflected or pulled in an unintended direction due to electromagnetic forces interacting with the arc. To minimize arc blow, take the following steps:

- Check grounding connections: Ensure that the workpiece and welding machine are properly grounded to reduce electromagnetic interference.

- Adjust amperage and electrode angle: Modifying the amperage and electrode angle can help redirect the arc and improve stability.

- Change welding direction: Changing the direction of the welding pass can help counteract arc blow and achieve a more stable arc.

Dealing with Sticking Electrodes

Sticking electrodes can be frustrating and may result in weld defects. If an electrode sticks to the metal surface, follow these steps to free it:

- Shut off the welding machine and let the electrode cool down to a safe temperature.

- Use a chipping hammer to gently tap the electrode to release it from the weld puddle.

- If necessary, regrind the electrode tip to remove any slag or contaminants before continuing the welding process.

Stick Welding Safety

Protective Gear

Stick welding involves potential hazards, so wearing the proper protective gear is essential for your safety. The following protective gear is recommended:

- Welding helmet: Protects your face and eyes from sparks, intense light, and harmful ultraviolet and infrared radiation.

- Welding gloves: Made from durable and heat-resistant materials, welding gloves safeguard your hands from burns, sparks, and electrical shocks.

- Flame-resistant clothing: Long-sleeved shirts, long pants, and fire-resistant jackets provide protection against sparks and heat.

- Steel-toed boots: Steel-toed boots protect your feet from potential impacts and falling objects.

Work Area Safety

Maintaining a safe work area is crucial to prevent accidents and injuries. Consider the following safety practices:

- Clear the work area: Remove any flammable materials, debris, or potential tripping hazards from the work area.

- Ensure proper lighting: Sufficient lighting helps visibility and reduces the risk of accidents.

- Secure the workpiece: Use clamps or supports to secure the workpiece, preventing movement during the welding process.

Proper Ventilation

Stick welding produces welding fumes and gases that can be harmful if inhaled. Ensure proper ventilation in your work area:

- Weld in a well-ventilated space: If working indoors, open windows or use ventilation fans to remove fumes effectively.

- Use exhaust systems: Local exhaust systems with fume extraction hoods can help capture and remove welding fumes.

Electrical Safety Precautions

Stick welding involves electricity, so it is essential to follow electrical safety precautions:

- Use the correct power supply: Ensure that your welding machine is properly grounded and connected to a suitable power source.

- Inspect cables and connections: Regularly check welding cables and connections for damage and wear. Replace any damaged cables or components.

- Avoid wet conditions: Do not use stick welding equipment in wet or damp areas to prevent electrical shocks.

Stick Welding vs. other Welding Methods

Comparison with MIG Welding

Stick welding and MIG (Metal Inert Gas) welding are both popular welding methods. Here is a comparison between the two:

- Stick welding is more versatile and can be used in outdoor or windy conditions, while MIG welding requires a controlled indoor environment.

- Stick welding is suitable for thicker materials and provides better penetration, whereas MIG welding is better for thinner materials and produces clean, aesthetically pleasing welds.

- Stick welding offers a lower start-up cost, as it requires less equipment and does not rely on shielding gas, while MIG welding demands a higher initial investment.

- MIG welding is generally faster than stick welding due to its continuous wire feed, while stick welding requires frequent electrode changes and may result in more downtime.

Comparison with TIG Welding

Stick welding and TIG (Tungsten Inert Gas) welding are distinct processes with different applications. Here is a comparison between the two:

- TIG welding produces high-quality, precise welds with excellent aesthetics, while stick welding may produce a less visually appealing weld due to splatter and slag.

- Stick welding offers better portability and flexibility, making it suitable for outdoor and field applications, while TIG welding is typically performed indoors and on clean materials.

- TIG welding is suited for thin materials and provides better control over the heat input, while stick welding is better for thicker materials and allows for welding in various positions.

- TIG welding requires more skill and technique to master, while stick welding is considered simpler and more forgiving.

- TIG welding requires an external shielding gas, while stick welding has a built-in flux coating on the electrode.

Comparison with Flux-Cored Arc Welding (FCAW)

Stick welding and Flux-Cored Arc Welding (FCAW) have similarities but also differences. Here is a comparison between the two:

- Both stick welding and FCAW use a flux-based coating to protect the weld from atmospheric contamination.

- Stick welding is generally more portable and suitable for outdoor applications, while FCAW is commonly used in heavy fabrication and construction due to its high deposition rates.

- FCAW can achieve higher welding speeds compared to stick welding, resulting in increased productivity.

- Stick welding typically requires more skill and practice to achieve quality welds, while FCAW is considered relatively easier to learn.

- FCAW typically requires a higher initial investment due to the cost of the welding machine and the consumable wire.

Stick Weld Quality Assessment

Visual Inspection

Visual inspection is an essential step in assessing stick weld quality. It involves examining the weld bead for various characteristics, such as:

- Uniformity: A quality stick weld should exhibit a uniform and consistent appearance throughout its length.

- Penetration: The weld should exhibit proper penetration, with the weld metal fused to the base metal without excessive undercutting or incomplete fusion.

- Slag: The presence of slag may be acceptable, but excessive amounts or slag inclusions can indicate poor weld quality.

- Spatter: While some spatter is normal, excessive spatter can indicate issues with the welding technique or improper welding parameters.

Non-Destructive Testing

Non-destructive testing methods can be employed to further assess the quality of stick welds. Common non-destructive testing methods include:

- Visual inspection: As mentioned earlier, visually inspecting the weld bead can provide valuable information about its quality.

- Liquid penetrant testing: This method involves applying a liquid penetrant to the weld surface and inspecting for any indications of surface-breaking defects.

- Magnetic particle testing: Magnetic particle testing uses magnetic fields and iron particles to detect surface and near-surface defects in ferromagnetic materials.

- Ultrasonic testing: Ultrasonic waves are used to detect internal defects, such as porosity, in the welded material.

Weld Quality Standards

Various organizations and standards provide guidelines and recommendations for stick weld quality. These standards may include specifications on materials, welding procedures, and acceptance criteria. Common standards and codes include those provided by the American Welding Society (AWS), American Society of Mechanical Engineers (ASME), and International Organization for Standardization (ISO). Adhering to these standards ensures the production of quality stick welds that meet industry requirements and specifications.

In conclusion, stick welding is a versatile and widely used welding process with its unique advantages and considerations. By understanding the basics, safety precautions, techniques, troubleshooting, and quality assessment, you can confidently engage in stick welding projects. As with any skill, continuous practice and learning will help you refine your stick welding abilities and achieve the best possible welds. Remember to prioritize safety, follow the recommended guidelines, and enjoy the rewarding experience of mastering the art of stick welding.